Parts of a bike frame – Prepare to unravel the intricacies of a bike frame, the backbone of any bicycle. Each component plays a pivotal role in ensuring a smooth and efficient ride. From the sturdy top tube to the supportive seat stays, we’ll embark on a journey to decipher the anatomy of this remarkable structure.

Delving deeper, we’ll explore the significance of the front and rear triangles, responsible for providing structural integrity. The bottom bracket and head tube emerge as crucial connectors, seamlessly integrating the frame’s elements.

Materials Used in Bike Frame Construction

The choice of material for a bike frame significantly impacts its performance, durability, and cost. Here’s an overview of the most commonly used materials and their properties:

Steel

Steel frames are known for their strength, durability, and affordability. They are relatively heavy but offer a comfortable ride due to their ability to absorb vibrations.

Aluminum

Aluminum frames are lightweight, strong, and corrosion-resistant. They provide a responsive and efficient ride, making them popular for road and mountain bikes.

Titanium

Titanium frames combine strength, lightness, and corrosion resistance. They are more expensive than steel and aluminum but offer exceptional durability and a comfortable ride.

Carbon Fiber

Carbon fiber frames are extremely lightweight, stiff, and strong. They provide excellent power transfer and handling, but can be expensive and susceptible to damage.

Bamboo

Bamboo frames are an eco-friendly alternative to traditional materials. They are lightweight, strong, and sustainable, but may require special care to maintain their durability.

| Material | Weight | Strength | Durability | Cost |

|---|---|---|---|---|

| Steel | High | High | Good | Low |

| Aluminum | Medium | High | Good | Medium |

| Titanium | Low | Very High | Excellent | High |

| Carbon Fiber | Very Low | Very High | Good | Very High |

| Bamboo | Medium | Medium | Good | Medium |

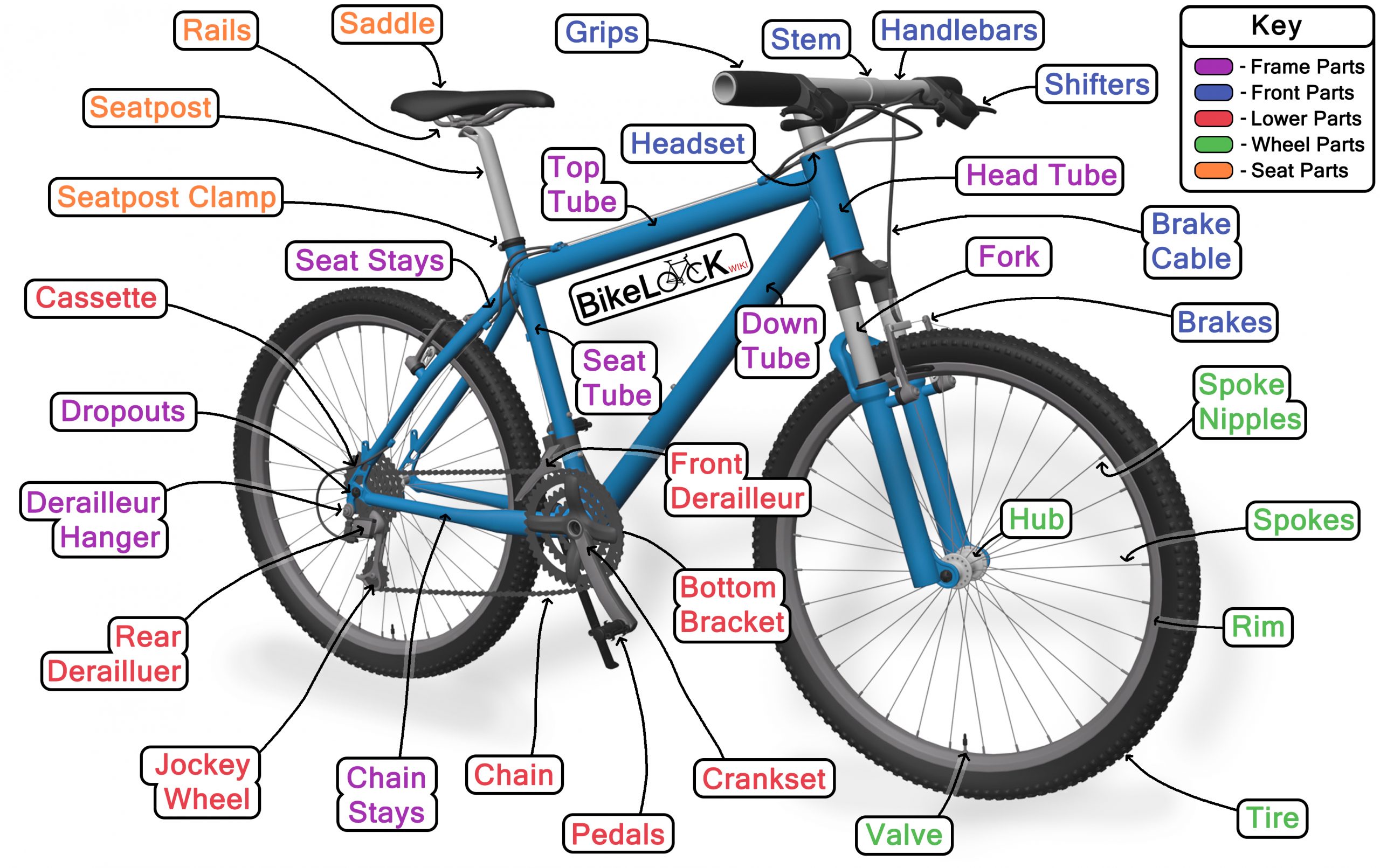

Main Frame Components

The main frame of a bicycle is the central structure that connects all the other components and provides the foundation for the bike’s handling and performance. It consists of several key components, each with a specific function.

Top Tube

The top tube runs from the head tube to the seat tube and provides structural support for the frame. It also determines the bike’s overall reach and handling characteristics.

Down Tube, Parts of a bike frame

The down tube runs from the head tube to the bottom bracket and is responsible for transferring pedaling forces to the rear wheel. It is typically the largest and strongest tube in the frame.

Seat Tube

The seat tube extends from the bottom bracket to the top of the frame and supports the saddle. It also plays a role in determining the bike’s seat height and saddle position.

Head Tube

The head tube connects the top tube, down tube, and fork, and provides a bearing surface for the headset. It determines the bike’s steering geometry and handling.

Seat Stays

The seat stays connect the seat tube to the rear dropouts and provide support for the saddle and rider’s weight. They also contribute to the bike’s overall stiffness and handling.

Front and Rear Triangles

The front and rear triangles of a bike frame form the backbone of the structure, providing rigidity and stability to the bike. They are interconnected by the seat tube, top tube, and down tube.

The front triangle, located at the front of the bike, consists of the head tube, down tube, and top tube. It supports the steering system and handlebars, and transfers the rider’s weight and force to the rear triangle.

If you’re looking to get the perfect fit on your bike, measuring the frame is essential. Luckily, it’s a simple process that anyone can do at home. For a step-by-step guide, check out this article: How to Measure Bike Frame . Once you’ve got the right frame size, you can start exploring different bike options.

One exciting choice is the Ebox Electric Pit Bike Stomp Dirt Bikes 2.0KW 60V 18.2Ah Lithium . With its powerful motor and durable construction, it’s the perfect ride for off-road adventures.

Rear Triangle

The rear triangle, located at the back of the bike, consists of the seat tube, seat stays, and chain stays. It supports the rider’s weight, the drivetrain components, and the rear wheel. The shape and design of the rear triangle can vary depending on the type of bike and its intended use.

Bottom Bracket and Head Tube

The bottom bracket and head tube play crucial roles in connecting the various components of a bike frame. The bottom bracket is located at the junction of the seat tube, down tube, and chain stays, providing a housing for the bearings that allow the cranks and pedals to rotate smoothly.

The head tube, on the other hand, is located at the front of the frame, where the fork and handlebars are attached.

Before you can hit the open road on your new set of wheels, it’s crucial to determine the right bike frame size. By following the steps outlined in this helpful guide , you can ensure a comfortable and efficient ride.

Proper measurement ensures that your body aligns optimally with the bike, maximizing your performance and minimizing discomfort.

Types of Bottom Brackets

There are several types of bottom brackets used in different bikes, each with its own advantages and disadvantages:

- Threaded Bottom Brackets:These are the most common type, featuring threads cut into the frame’s shell. They are easy to install and maintain but can be prone to creaking and require periodic adjustment.

- Press-Fit Bottom Brackets:These are pressed into the frame’s shell, providing a more secure and creak-free connection. However, they can be more difficult to install and remove.

- BB30 Bottom Brackets:These are oversized press-fit bottom brackets that use larger bearings for increased stiffness and durability. They are commonly found on high-performance bikes.

Types of Head Tubes

Head tubes also vary in design and dimensions, depending on the bike’s intended use:

- Tapered Head Tubes:These head tubes have a larger diameter at the bottom than at the top, providing increased stiffness and strength for the front end of the bike.

- Straight Head Tubes:These head tubes have the same diameter throughout their length, making them simpler to manufacture but less stiff than tapered head tubes.

- Integrated Headsets:These head tubes feature bearings that are built directly into the frame, eliminating the need for a separate headset. They offer a clean and sleek look but can be more expensive to replace.

Dropouts and Chainstays

Dropouts and chainstays are essential components of a bike frame that support the rear wheel and provide a stable base for the drivetrain. Dropouts are the anchor points where the rear wheel axle is secured, while chainstays connect the dropouts to the bottom bracket.

There are different types of dropouts and chainstays used in different bikes, depending on the intended purpose and design of the bike.

Horizontal Dropouts

Horizontal dropouts are commonly found on single-speed and fixed-gear bikes. They allow for easy wheel removal and adjustment by sliding the wheel forward or backward in the dropouts. However, horizontal dropouts do not provide as much lateral stability as other types of dropouts.

Vertical Dropouts

Vertical dropouts are used on most modern bikes, including road bikes, mountain bikes, and hybrids. They provide more lateral stability than horizontal dropouts, making them suitable for bikes that are likely to encounter rough terrain or heavy loads.

If you’re an adrenaline junkie craving the thrill of off-road adventures, consider the ebox electric pit bike stomp dirt bikes 2.0kw 60v 18.2ah lithium . This high-powered machine boasts a robust lithium battery, ensuring an exhilarating ride on challenging terrains.

With its rugged construction and agile handling, you’ll conquer every bump and conquer the wilderness with ease.

Chainstays

Chainstays come in various shapes and sizes, depending on the bike’s intended use. Road bikes typically have thin, lightweight chainstays to minimize weight and improve efficiency. Mountain bikes have thicker, more robust chainstays to withstand the rigors of off-road riding.

Fork and Headset

The fork is a crucial component that connects the front wheel to the frame, allowing for steering and supporting the front end of the bike. The headset is a set of bearings that enables the fork to rotate smoothly within the head tube of the frame.

There are various types of forks and headsets designed for different bike disciplines and preferences. Road bikes typically use lightweight carbon or aluminum forks with narrow tires for speed and efficiency, while mountain bikes often have wider, suspension-equipped forks to handle rough terrain.

Fork Types

- Rigid Forks:These forks have no suspension and are commonly found on road bikes and entry-level mountain bikes. They provide a more direct and responsive ride feel.

- Suspension Forks:These forks feature a shock absorber or air spring to absorb bumps and improve comfort and control on rough terrain. They are essential for mountain biking and other off-road cycling disciplines.

Headset Types

- Threaded Headsets:These headsets use a threaded fork steerer tube that screws into the head tube. They are commonly found on older bikes and are relatively easy to maintain.

- Threadless Headsets:These headsets use a press-fit fork steerer tube that is inserted into the head tube without threading. They are lighter and provide a smoother steering action compared to threaded headsets.

Geometry and Fit

Bike frame geometry is crucial for both rider comfort and performance. It determines how well the bike fits the rider’s body and riding style. A well-fitted bike allows for an efficient and comfortable riding experience, while a poorly fitted bike can lead to discomfort, pain, and reduced performance.

Frame Size and Fit Measurements

Determining the correct bike frame size involves measuring several key dimensions:

- Standover height:The distance from the top of the top tube to the ground. It ensures the rider can straddle the bike comfortably without hitting their groin.

- Seat tube length:The distance from the center of the bottom bracket to the top of the seat tube. It determines the height of the saddle.

- Top tube length:The distance between the center of the head tube and the center of the seat tube. It affects the rider’s reach to the handlebars.

- Head tube angle:The angle between the head tube and the ground. It influences the bike’s handling and stability.

- Seat tube angle:The angle between the seat tube and the ground. It affects the rider’s position on the bike.

These measurements are used to determine the ideal frame size for the rider’s height, leg length, and riding style. A professional bike fitter can help ensure a precise fit.

Manufacturing Processes

The manufacturing process of bike frames involves shaping and joining the frame’s components to create a rigid and lightweight structure. Several techniques are employed, each with its advantages and drawbacks.

Welding

Welding is a common method of joining metal components by melting and fusing them together. In bike frame construction, welding is typically done using either TIG (tungsten inert gas) or MIG (metal inert gas) welding techniques. TIG welding provides precise and strong welds, while MIG welding is faster and more cost-effective.

Advantages:

- Strong and durable welds

- Can be used with a variety of metals

- Allows for complex frame designs

Disadvantages:

- Requires skilled welders

- Can create heat-affected zones that weaken the metal

- Can be more expensive than other methods

Brazing

Brazing is similar to welding but uses a lower melting point alloy to join the metal components. This process creates a strong bond but does not melt the base metals. Brazing is often used for joining dissimilar metals or for creating fillets and lugs.

Advantages:

- Strong and durable joints

- Can be used with a variety of metals

- Less heat-affected zone than welding

Disadvantages:

- Requires skilled brazers

- Can be more time-consuming than welding

- May not be suitable for all frame designs

Molding

Molding is a process of shaping a material by pouring it into a mold and allowing it to solidify. In bike frame construction, molding is primarily used for carbon fiber frames. The carbon fiber is mixed with a resin and poured into a mold, which is then heated and pressurized to create a strong and lightweight frame.

Advantages:

- Can create complex shapes

- Produces lightweight and stiff frames

- Allows for precise control over frame dimensions

Disadvantages:

- Requires expensive molds

- Can be time-consuming and labor-intensive

- May not be suitable for all frame materials

Custom Bike Frames

Custom bike frames are designed and built to meet the specific needs and preferences of individual riders. They are meticulously crafted to provide an optimal fit, performance, and riding experience.The process of designing a custom frame involves several key steps:

-

-*Consultation

The frame builder consults with the rider to gather information about their size, riding style, and intended use for the bike. This information is crucial for determining the frame’s geometry, materials, and components.

-*Design

Based on the consultation, the frame builder creates a detailed design for the frame. This includes determining the frame’s shape, tube diameters, and angles. The design is carefully optimized to ensure the frame meets the rider’s requirements.

-*Fabrication

The frame is fabricated using a combination of techniques, including welding, brazing, and machining. The frame builder carefully joins the tubes and components to create a strong and durable frame.

-*Finishing

Once the frame is fabricated, it undergoes a finishing process. This may include painting, anodizing, or powder coating to protect the frame from corrosion and enhance its appearance.

When designing a custom frame, several factors are considered:

-

-*Rider Size

The frame’s geometry must be tailored to the rider’s height, inseam, and arm length. This ensures a comfortable and efficient riding position.

-*Riding Style

The frame’s design should complement the rider’s preferred riding style. For example, a frame designed for racing will have a more aggressive geometry than a frame intended for recreational riding.

-*Intended Use

The frame’s materials and construction should be appropriate for the intended use of the bike. A frame designed for off-road riding will need to be more robust than a frame intended for road racing.

Custom bike frames offer several advantages over mass-produced frames. They provide a perfect fit, allowing riders to maximize their comfort and performance. Additionally, custom frames can be tailored to specific aesthetic preferences, resulting in a unique and personalized bike.

Final Conclusion

Our exploration concludes with an understanding of bike frame geometry, a crucial factor in achieving optimal comfort and performance. Custom bike frames, tailored to individual preferences, showcase the artistry and precision involved in crafting these remarkable machines.

Common Queries: Parts Of A Bike Frame

What materials are commonly used in bike frame construction?

Steel, aluminum, titanium, carbon fiber, and bamboo are popular materials employed in bike frame construction.

What is the function of the bottom bracket?

The bottom bracket connects the crankset to the frame, enabling pedaling and transferring power to the rear wheel.

How do dropouts contribute to the bike frame?

Dropouts provide support for the rear wheel and allow for easy wheel removal and installation.

What is the significance of bike frame geometry?

Bike frame geometry influences rider comfort, efficiency, and handling characteristics.