Parts of bike frame – Embark on a journey through the intricate world of bicycle frame components, where each part plays a vital role in shaping the ride experience. From the primary structural elements to the choice of materials and design, discover the secrets that lie within the backbone of your bike.

Delve into the various frame materials, each offering unique advantages and drawbacks, and explore the geometry that determines your riding position and handling. Understand the different frame designs and how they impact performance, and gain insights into the manufacturing process that brings these frames to life.

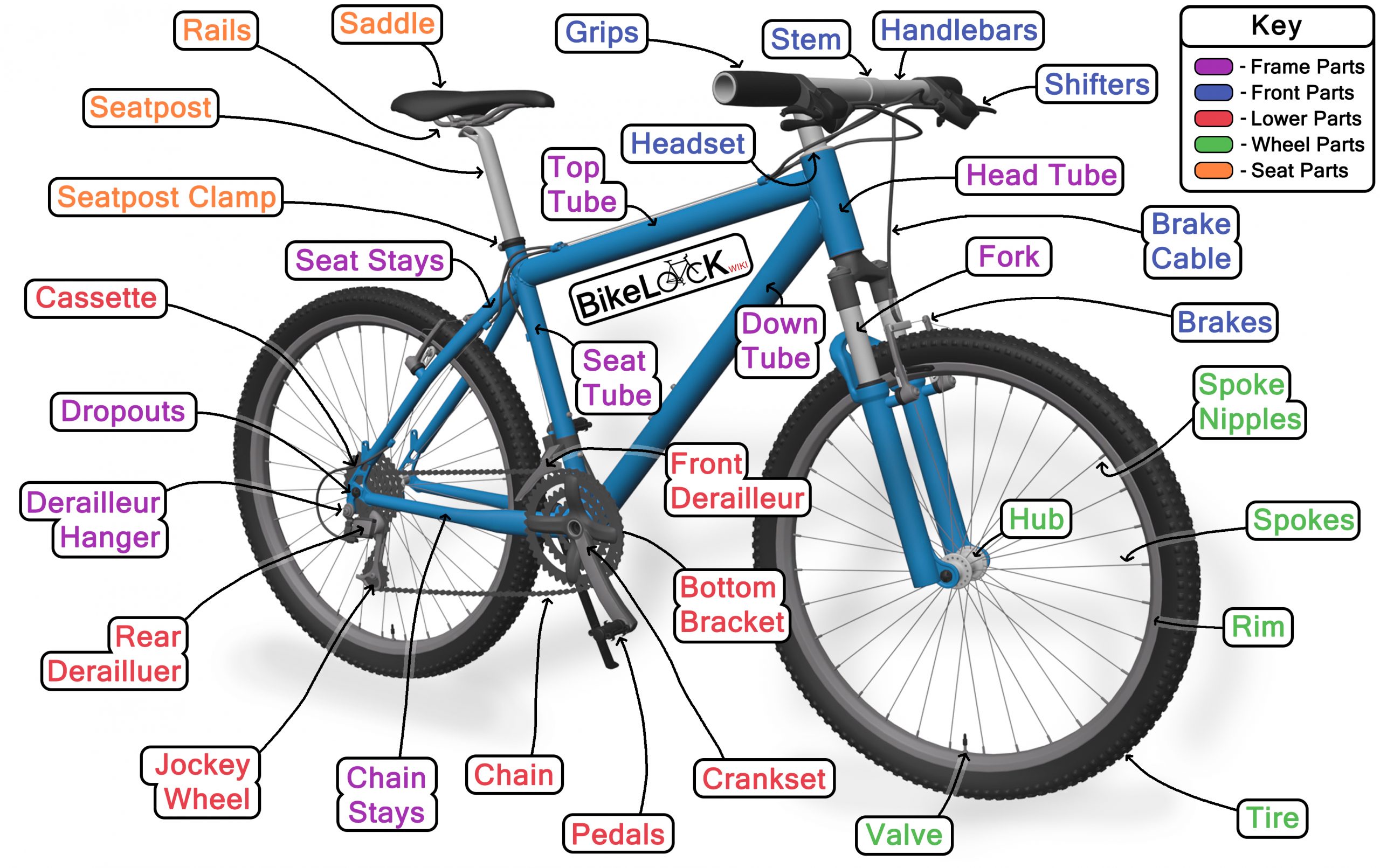

Main Frame Components

The frame of a bicycle is the primary structural component that supports the rider and the various components of the bike. It consists of several key parts, each with a specific purpose and function.

Head Tube

- Connects the front fork to the rest of the frame.

- Houses the headset bearings, which allow the handlebars to turn smoothly.

- Determines the height and reach of the handlebars.

Top Tube

- Runs from the head tube to the seat tube.

- Provides support for the rider’s weight and helps transfer power from the pedals to the rear wheel.

- Its length and angle affect the overall geometry and handling of the bike.

Down Tube

- Runs from the head tube to the bottom bracket.

- Carries the majority of the rider’s weight and provides structural rigidity.

- Its size and shape influence the strength and stiffness of the frame.

Seat Tube

- Connects the top tube to the bottom bracket.

- Supports the seatpost and saddle.

- Its angle and length determine the seat height and the overall riding position.

Bottom Bracket

- Connects the seat tube, down tube, and chainstays.

- Houses the bearings that allow the crankset to rotate.

- Its width and type determine the compatibility of the crankset and drivetrain components.

Chainstays

- Run from the bottom bracket to the rear dropouts.

- Support the rear wheel and transfer power from the pedals to the wheel.

- Their length and angle affect the wheelbase and handling characteristics of the bike.

Seat Stays

- Run from the seat tube to the rear dropouts.

- Provide support for the rider’s weight and help absorb road vibrations.

- Their length and angle influence the ride quality and comfort of the bike.

Rear Dropouts

- Attach the rear wheel to the frame.

- Allow for adjustment of the wheel position for proper chain tension.

- Can be designed for different types of wheel mounting systems, such as quick-release or thru-axles.

Frame Materials

The frame of a bicycle is its structural backbone, responsible for supporting the rider, drivetrain, and various components. The choice of material used in frame construction has a significant impact on the overall performance, durability, and cost of the bicycle.

Bicycle frames are primarily constructed from three main materials: steel, aluminum, and carbon fiber. Each material offers distinct advantages and disadvantages, catering to different riding styles and budgets.

Steel

Steel is a traditional and widely used material for bicycle frames, offering a combination of strength, durability, and affordability. Steel frames are relatively easy to repair, making them a popular choice for commuters and recreational riders.

Advantages:

- Durable and robust

- Easy to repair

- Affordable compared to other materials

Disadvantages:

- Heavier than aluminum or carbon fiber

- Prone to corrosion if not properly maintained

- Less efficient than lighter materials

Examples:Surly Long Haul Trucker, Kona Rove, Trek Domane

Aluminum, Parts of bike frame

Aluminum is a lightweight and strong material, making it a popular choice for performance-oriented bicycles. Aluminum frames offer a good balance of stiffness and compliance, providing a responsive and comfortable ride.

Advantages:

- Lightweight and stiff

- Durable and resistant to corrosion

- More affordable than carbon fiber

Disadvantages:

- Not as compliant as steel or carbon fiber

- More difficult to repair than steel

- Can be prone to fatigue over time

Examples:Giant Defy, Specialized Allez, Cannondale Synapse

If you’re looking for a new rear wheel for your 6-inch mini bike, you’ll want to check out the 6 inch mini bike rear wheel . It’s made of high-quality materials and is designed to withstand the rigors of off-road riding.

Carbon Fiber

Carbon fiber is a high-performance material known for its exceptional strength-to-weight ratio. Carbon fiber frames are extremely lightweight, stiff, and durable, providing an unmatched ride quality and efficiency.

Advantages:

- Extremely lightweight and stiff

- Excellent vibration damping

- Resistant to corrosion and fatigue

Disadvantages:

- Expensive compared to other materials

- More difficult to repair than steel or aluminum

- Can be brittle if not handled properly

Examples:Trek Émonda, Specialized Tarmac, Cervélo R5

Frame Geometry

Bicycle frame geometry is a crucial aspect of bike design that determines the riding position, handling characteristics, and overall comfort of the rider. It involves measuring and adjusting various angles and dimensions of the frame to optimize the bike for specific riding styles and terrains.

Key frame measurements include:

- Seat tube length:Vertical distance from the bottom bracket to the top of the seat tube, affecting saddle height and leg extension.

- Top tube length:Horizontal distance between the head tube and the seat tube, influencing reach and overall bike length.

- Head tube angle:Angle formed by the head tube and the ground, affecting steering stability and responsiveness.

- Seat tube angle:Angle formed by the seat tube and the ground, impacting rider’s position and weight distribution.

- Chainstay length:Distance between the bottom bracket and the rear wheel axle, influencing acceleration and rear wheel traction.

These measurements are interdependent and must be carefully balanced to achieve the desired riding experience. For instance, a longer top tube provides a more stretched-out position, while a shorter one offers a more upright and comfortable ride.

Frame geometry varies depending on the type of bicycle. Road bikes typically have a longer top tube and a steeper head tube angle for an aggressive, aerodynamic riding position. Mountain bikes, on the other hand, have a shorter top tube and a slacker head tube angle for increased stability and maneuverability on rough terrain.

Understanding frame geometry is essential for selecting a bike that fits well and meets your specific riding needs. It allows you to adjust the bike to achieve the optimal riding position, ensuring comfort, efficiency, and overall enjoyment.

Frame Design

The design of a bicycle frame significantly influences its performance, handling, and overall ride quality. There are numerous types of frame designs, each with its own advantages and disadvantages. Here’s a closer look at some common frame designs:

Diamond Frame

The diamond frame is the most prevalent design, featuring two main triangles formed by the top tube, down tube, seat tube, and seat stays. It offers a balance of strength, stiffness, and weight, making it suitable for a wide range of riding styles.

Road bikes, mountain bikes, and hybrid bikes often utilize this design.

Step-Through Frame

The step-through frame is characterized by a lowered top tube, creating a step-over height that is lower than the diamond frame. This design makes it easier to mount and dismount the bicycle, making it a popular choice for city bikes, comfort bikes, and e-bikes.

Recumbent Frame

Recumbent frames place the rider in a reclined position, with their legs extended forward. This design offers improved aerodynamics and can be more comfortable for riders with back or neck issues. However, recumbent bikes are typically heavier and less maneuverable than upright bikes.

Embark on an unforgettable cycling adventure along the picturesque Hudson Valley Bike Ride. As you glide through lush landscapes, keep an eye out for the sleek 6-inch mini bike rear wheel here . This compact wheel offers superior maneuverability and stability, making it the perfect choice for navigating the ride’s challenging terrain.

Folding Frame

Folding frames allow the bicycle to be folded into a compact size for storage or transportation. These frames are often used for commuter bikes, touring bikes, and urban cyclists who need to save space.

Full-Suspension Frame

Full-suspension frames incorporate suspension systems at both the front and rear wheels. This design provides maximum shock absorption, making it ideal for rough terrain and off-road riding. However, full-suspension frames are typically heavier and more expensive than hardtail frames.

Hardtail Frame

Hardtail frames have a suspension system only at the front wheel. This design offers a balance between comfort and efficiency, making it suitable for a variety of riding conditions. Hardtail bikes are often used for mountain biking, cyclocross, and gravel riding.

Frame Manufacturing

The creation of a bicycle frame, the backbone of the bike, involves a series of meticulous steps and techniques. These methods, ranging from traditional craftsmanship to cutting-edge technology, play a crucial role in determining the frame’s durability, performance, and overall quality.

The choice of manufacturing technique depends on various factors, including the material used, the desired frame geometry, and the manufacturer’s capabilities. Each technique offers its own advantages and drawbacks, which we will explore in detail.

Frame Manufacturing Techniques

| Technique | Pros | Cons |

|---|---|---|

| Welding | – Strong and durable joints – Suitable for a wide range of materials – Relatively low cost | – Requires skilled labor – Can create heat-affected zones – May not be suitable for complex geometries |

| Brazing | – Strong and ductile joints – Allows for complex geometries – Can be used with a variety of materials | – Requires higher temperatures than welding – Can be more time-consuming – May not be as strong as welded joints |

| Lugged Construction | – Strong and durable – Allows for easy repairs and upgrades – Classic and aesthetically pleasing | – More labor-intensive and expensive – Not suitable for all materials – May not be as lightweight as other methods |

| Monocoque Construction | – Lightweight and stiff – Allows for complex geometries – Strong and durable | – Requires specialized equipment and expertise – More expensive than other methods – Difficult to repair |

| Carbon Fiber Layup | – Lightweight and stiff – Allows for complex geometries – Strong and durable | – Requires specialized equipment and expertise – More expensive than other methods – Difficult to repair |

In addition to these traditional methods, new and innovative techniques are constantly being developed, such as 3D printing and hydroforming. These methods offer the potential for even lighter, stronger, and more complex frame designs in the future.

Frame Maintenance

Preserving the integrity of your bike’s frame is essential for safety and longevity. Proper maintenance prevents premature wear, corrosion, and structural damage, ensuring your bike remains reliable and enjoyable to ride.

Here are some essential tips for maintaining your bike frame:

Cleaning and Lubrication

- Regularly clean the frame with a mild detergent and water to remove dirt, grime, and road salt.

- Lubricate moving parts such as the headset, bottom bracket, and seatpost to reduce friction and prevent wear.

Inspection and Adjustments

- Periodically inspect the frame for cracks, dents, or other damage. These can compromise the frame’s integrity and should be addressed promptly.

- Adjust the frame’s components, such as the headset and bottom bracket, to ensure proper fit and function.

Protection

- Use frame protectors or tape to prevent scratches and scuffs from cables and other components.

- Store your bike in a dry, sheltered location to minimize exposure to moisture and extreme temperatures.

Common Frame Issues and Solutions

- Cracks:Cracks can occur due to excessive stress, impact, or fatigue. If a crack is detected, stop riding the bike immediately and consult a professional mechanic for repair or replacement.

- Dents:Minor dents can be unsightly but may not affect the frame’s structural integrity. Larger dents may require professional repair to restore the frame’s shape and strength.

- Corrosion:Corrosion can weaken the frame and lead to premature failure. Protect the frame from moisture by cleaning and lubricating it regularly and storing it in a dry environment.

End of Discussion: Parts Of Bike Frame

As we conclude our exploration of bike frame components, remember that proper maintenance is paramount to ensuring a long and reliable lifespan for your ride. By understanding the intricacies of your frame, you empower yourself to make informed decisions about customization and repairs, maximizing your cycling adventures.

Commonly Asked Questions

What are the main components of a bike frame?

The main components include the head tube, top tube, down tube, seat tube, seat stays, and chain stays.

What are the most common frame materials?

Steel, aluminum, carbon fiber, and titanium are the most widely used materials.

How does frame geometry affect the ride?

Geometry influences factors such as rider position, handling, stability, and overall comfort.